Description

Cavitation. Something you don’t want in your shock absorber. It’s devastating because basically it means the damping is lost. Small bubbles in the oil can never create the necessary damping forces. Traditional dampers working in extreme conditions sometimes suffers from low pressure on the piston backside.

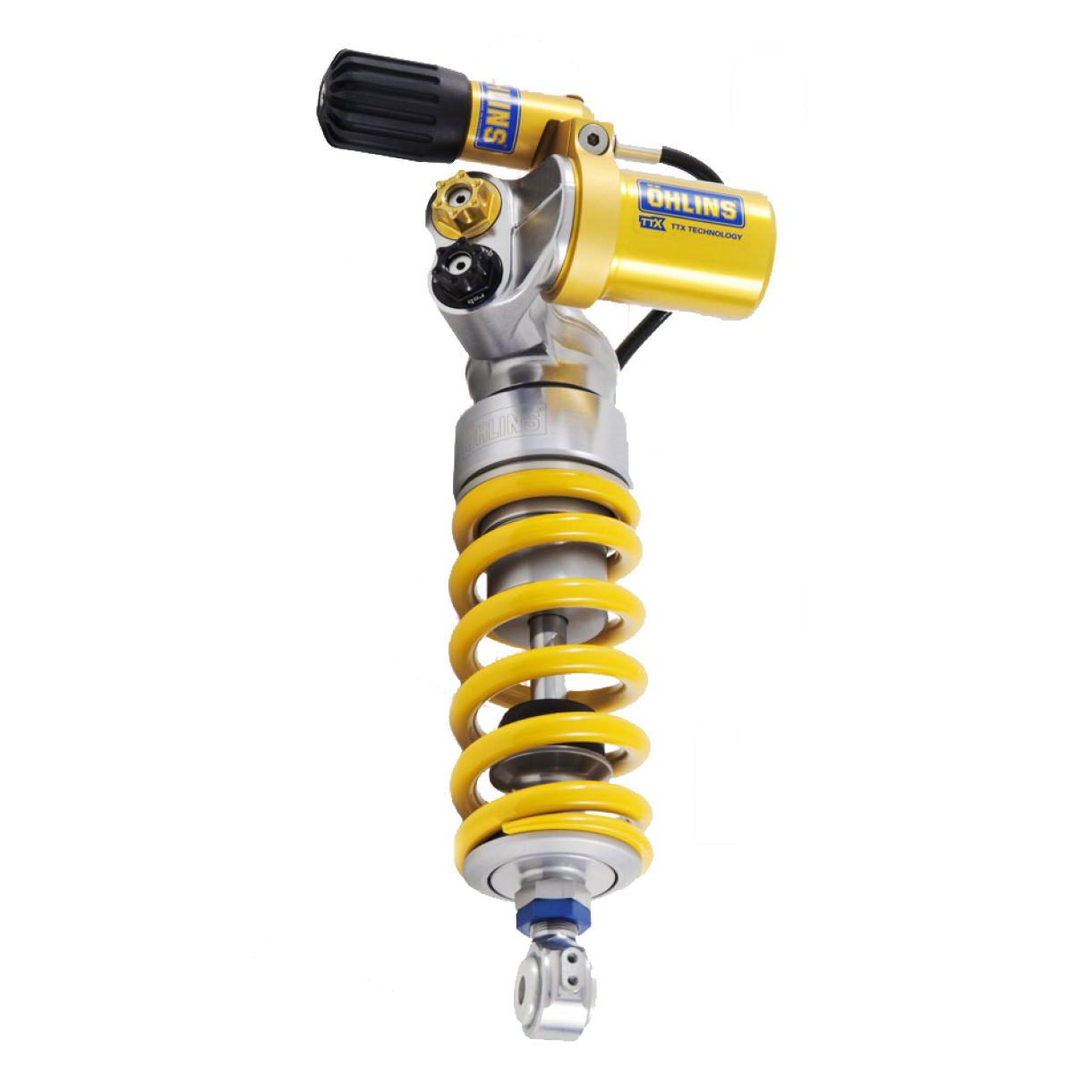

The TTX was created by Öhlins engineers to eliminate the risk for cavitation. They succeeded. With the TTX technology a positive pressure balance is created in the shock which means the risk for cavitation is gone.

TTX stands for Twin Tube with the X illustrating how the flow through the valves in the cylinder head is designed. Thanks to the twin tube technology the pressure usually created on top of the piston is transferred through the cylinder head and the adjusters for compression and rebound, then flows through the space between the inner and outer tube to the other side of the solid piston.

These equals to a pressure balance within the shock. The outer reservoir is only used to take care of the oil displacement from the piston rod and heat expansion, which is why it can be fairly small in design. Inside the reservoir there is a dividing piston between the oil and the nitrogen gas.

The gas pressurizes the oil to a level between six and nine bars, basically the static pressure on both sides of the solid piston. TTX technology is also used with a lot of success in the racing cartridge kits and front forks.

As with a lot of new technology from Öhlins the TTX technology was first introduced in racing after an intensive testing period and it instantly delivered a lot of wins and championships.

Just two years later it was available to any privateer and quickly adapted to street applications as well. After a lot of success in racing and the sport and hypersport segment, it has now also been made available for Adventure type bikes.

The TTX layout also makes these shocks ideal to use for electronically controlled (EC) suspension.

Reviews

There are no reviews yet.